mobile: 07885 881008 - 07841 470868

workshop: 01638 781 882

info@aquablast.uk.com

Our Other In House Services

Aluminium Welding

In addition to our Aqua/vapor blasting service we also carry out repairs any engine cases, gearbox casting or any car or motorcycle component, we have the technology and “Know How” to make or repair most things, if you have a project that needs an aluminium repair please contact us, we will be able to determine if the project is viable and provide you with a costing.

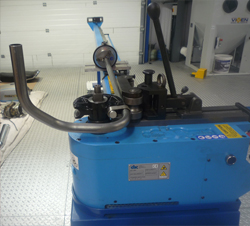

Tube Bending & Ring Rolling

We have an in house mandrel bender and ring roller for 1off or multiple bends from 20mm OD tube to 40mm OD tube also 25mm square tube ideal for your custom builds and restorations.

Milling and Turning

Milling

Conventional milling is covered by a universal milling machine with a table 1700mm x 400mm which is fitted with a full three axis digital readout.

Turning

We are able to turn various smaller components from 10mm up to a maximum of 430mm diameter with a maximum length between centres of 1520mm.

Sheet Metal Work

We offer a light fabrication service based on customer specifications in steel, stainless steel and aluminium, we offer the service for custom bikes and motorcycle and car restorations.